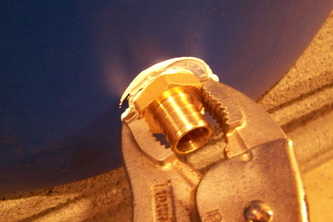

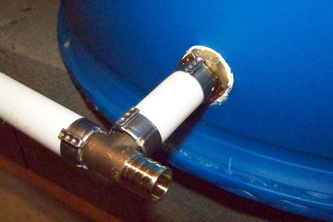

I drilled out some 2” plumbing cast iron threaded end caps with hole saws. One with muffler port clearance (7/8”) and the other end cap 1 -1/4”, which allows clearance for a zinc plated EMT conduit threaded fitting. I also needed to drill an access hole in the side of the end cap on the muffler side so I could tighten/loosen the internal clamp collar on the muffler port. I then connected the two end caps with a piece of aluminum flexible tubing. (The generator’s engine moves around on its rubber mounts and thus requires a non-fixed exhaust hose.) Support the middle of the aluminum hose with a piece of metal wire, to further reduce stress on the hose. Clamp collars hold everything in place.

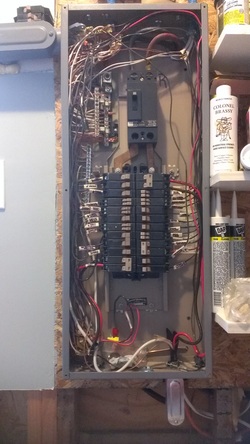

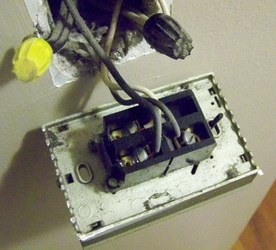

Lastly, we fabricated a mechanical breaker interlock out of ¼” Lexan. The interlock ensures that you will never have the main breaker in the on position while the generator is in the on position. There are kits available for purchase online for almost any panel if you are not feeling ambitious. In order to make the Lexan, you will need to make a slew of measurements and make a template out of cardboard. Lexan is much easier to cut and trim than steel, so it is totally doable. The kits that you get online come with UL certification sticker, a homemade kit does not. So proceed accordingly. The tricky part of making the Lexan for our 150Amp Cutler Hammer panel, was getting the generator lockout tab to fit in-between the 30 amp double pole handle and the breaker below when in the “generator on” position. The slots and where you drill the holes in the dead front panel are also key - take your time and measure twice.

When switching between main breaker and the generator power, ensure that you switch off the branch breakers to eliminate damage to your electronic devices.

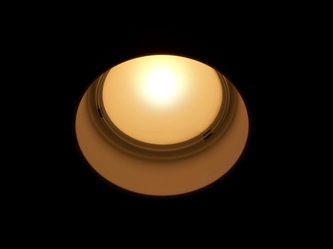

Our home has lots of LED lights, a high efficiency fridge and a tankless water heater – so fortunately, the 3200 watt generator has enough power to keep our whole home running. Keep in mind, running an oven, microwave, and other high wattage devices simultaneously will not work with a 3200 watt generator – you will need a generator with more power and a larger input breaker.

Good luck with your generator installation project. Witnessing your home running off generator power for the first time is pretty sweet. If your budget permits, you might consider a natural gas generator or an automatic transfer switch – but we wanted to show you how to get a system up and running as simply as possible.

RSS Feed

RSS Feed